Motor

Motor

Overview

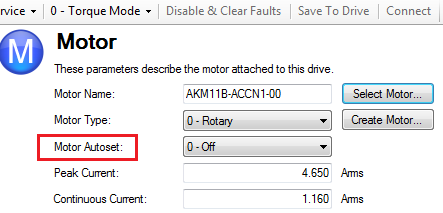

The Motor screen is used to set up or confirm the parameters of the motor connected to the drive. In certain cases, based on the feedback type, the motor parameters will automatically be set. The drive will auto-detect feedback devices that are preset with the appropriate feedback and motor parameters when AXIS#.MOTOR.AUTOSET is set to 1 (default). The values the drive uses for commutation, current, and velocity loop gains will be populated automatically.

If your motor does not have a plug and play feedback device![]() A process whereby some proportion of the output signal of a system is passed (fed back) to the input.

In automation, a device coupled to each motor to provide indication of the motor's shaft angle, for use in commutating the motor and controlling its speed and position, then you must turn off the motor autoset feature as shown in the screenshot below (AXIS#.MOTOR.AUTOSET = 0) and select the appropriate motor from the motor parameter database.

A process whereby some proportion of the output signal of a system is passed (fed back) to the input.

In automation, a device coupled to each motor to provide indication of the motor's shaft angle, for use in commutating the motor and controlling its speed and position, then you must turn off the motor autoset feature as shown in the screenshot below (AXIS#.MOTOR.AUTOSET = 0) and select the appropriate motor from the motor parameter database.

All of the appropriate Kollmorgen motors compatible with the AKD2G drive are contained in the motor database. For motors that are not listed, click Select Motor to open a custom motor view in which you can input the appropriate motor parameters.

Motor Setup

When motor autoset is on (AXIS#.MOTOR.AUTOSET = 1), the AKD2G will automatically configure motor parameters from the data stored in a supported feedback device (see Feedback Devices for supported devices on Kollmorgen motors). If your motor is detected automatically, the parameters in the Motor view are shaded and not accessible. If you have a non-plug and play feedback device (such as an incremental encoder or resolver), you can use this screen to enter motor data. Other motors can be configured from the Selecting a Motor screen.

Using the Motor View

The Motor view displays parameters related to the specific motor attached to the drive as follows:

- Motor Name (AXIS#.MOTOR.NAME ): The motor part number read from the autoset device, or the name from the motor database. When entering a custom motor name, the motor name should not contain any spaces.

- Motor Type (AXIS#.MOTOR.TYPE ): This field allows you to select the proper electromagnetic and control parameters for a rotary motor.

- Field Weakening (AXIS#.MOTOR.FIELDWEAKENING): This field allows a surface permanent magnet motor to operate above rated speed, at a constant power with reduced torque

Torque is the tendency of a force to rotate an object about an axis. Just as a force is a push or a pull, a torque can be thought of as a twist. This field can only be set when AXIS#.MOTOR.TYPE = 0.

Torque is the tendency of a force to rotate an object about an axis. Just as a force is a push or a pull, a torque can be thought of as a twist. This field can only be set when AXIS#.MOTOR.TYPE = 0. - Motor Autoset (AXIS#.MOTOR.AUTOSET): When set to 1, the drive automatically sets up a plug and play motor. When set to 0, you can access the motor database to select a catalog or custom motor.

The next set of parameters displayed are specific to the electrical and mechanical characteristics of the motor connected to the AKD2G drive.

- Continuous Current (AXIS#.MOTOR.ICONT ): Continuous current rating in Amps rms

- Peak Current (AXIS#.MOTOR.IPEAK ): Peak current rating in Amps rms.

- Coil Thermal Constant (AXIS#.MOTOR.CTF0): Coil thermal time constant in mHz.

- Inductance (quad, line-line) (AXIS#.MOTOR.LQLL ): Inductance for quadrature (torque producing) axis in milliHenries.

- Inductance (direct, line-line) (AXIS#.MOTOR.LDLL): Inductance for direct (flux producing) axis in milliHenries.

- Inductance Saturation (AXIS#.MOTOR.LISAT): Quadrature axis inductance saturation characteristic.

- Motor Poles (AXIS#.MOTOR.POLES ): Number of motor poles.

- Motor Phase (AXIS#.MOTOR.PHASE ): Phase offset in degrees used to set motor commutation as required. For most devices this is set to 0.

- Inertia (AXIS#.MOTOR.INERTIA ): Rotor inertia in Kg-cm^2.

- Torque

Torque is the tendency of a force to rotate an object about an axis. Just as a force is a push or a pull, a torque can be thought of as a twist Constant (AXIS#.MOTOR.KT

): Proportionality constant for generated torque as a function of current in Nm/Arms.

Torque is the tendency of a force to rotate an object about an axis. Just as a force is a push or a pull, a torque can be thought of as a twist Constant (AXIS#.MOTOR.KT

): Proportionality constant for generated torque as a function of current in Nm/Arms. - EMF Constant (AXIS#.MOTOR.KE ): Proportionality contstant for voltage generated at the motor coils as a function of speed.

- Motor Resistance (AXIS#.MOTOR.R ): Winding resistance in Ohms.

- Maximum Voltage (AXIS#.MOTOR.VOLTMAX

): Maximum rated voltage in Vrms

rms stands for root mean square (also known as the quadratic mean).

rms stands for root mean square (also known as the quadratic mean). - Maximum Speed (AXIS#.MOTOR.VMAX ): Maximum rated speed .

Selecting a Motor

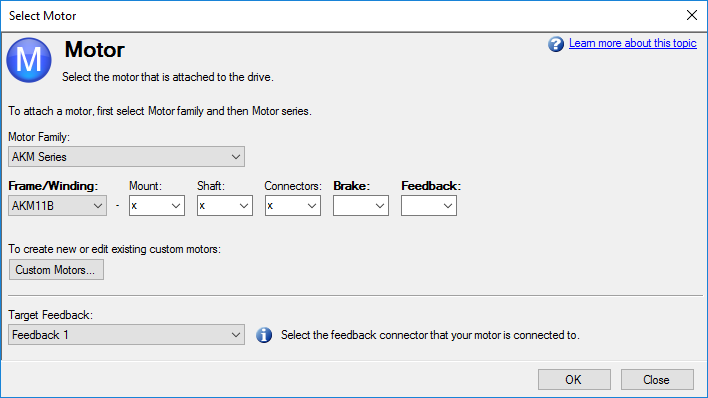

The Select Motor button opens a screen in which you can configure a non-plug and play motor or custom motor.

When this screen is opened, WorkBench displays by default the motor that matches the current motor name attached to the axis. WorkBench searches for a matching motor as follows:

- WorkBench first checks the motor name with custom motors for a match.

- If a match is not found, then WorkBench checks the name with the standard motors database for a match.

- If a match is not found, then an AKM motor is selected.

For non-plug and play motors, a database of catalog motors is available based on the different Kollmorgen motor families. When you select a motor family, a part number is displayed according to the selected motor family. You can change the part number as needed, and the complete motor name will be displayed according to your selection. This complete motor name is sent to drive. The portions of the part number labeled in bold are required values.

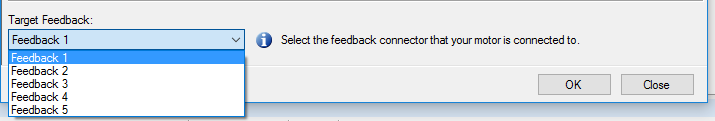

The Target Feedback selects which feedback connector the motor is connected to.

If the target feedback is changed, AXIS#.IL.FBSOURCE will be changed automatically to make the commutation source match the correct feedback. AXIS#.VL.FBSOURCE and AXIS#.PL.FBSOURCE will be changed to 0, to use the same source as AXIS#.IL.FBSOURCE.

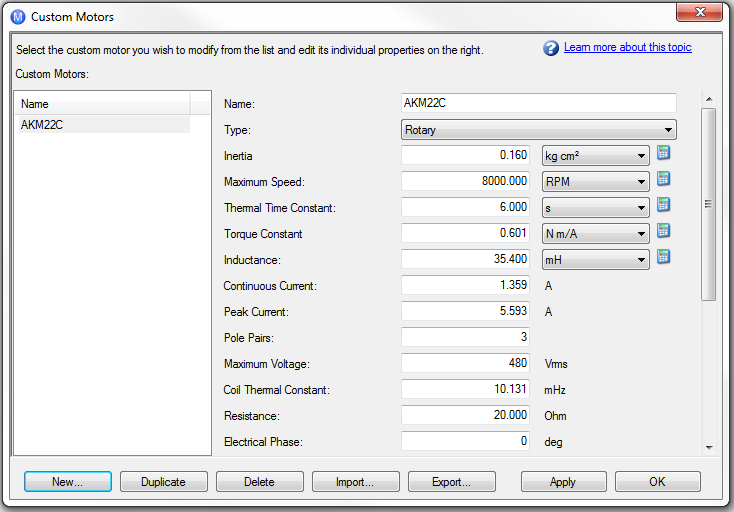

Configuring Custom Motors

From the Select Motor screen, click on Custom Motor to create and edit custom motors in the following screen:

In this view, you can import or export a motor parameter file, or create a custom motor of your choice. The appropriate parameters must be chosen as listed. Several of the parameters allow you to select an alternate unit of measure. When building a custom motor file, do not use blank spaces in the name you choose. Once you have configured one or more custom motors, if you select a custom motor from the list and click OK, then the selected custom motor will be displayed in the Select Motor screen.

The actions available in the custom motor screen include:

- New. Allows you to start a new custom motor (with default values) or load a catalog motor you may want to modify.

- Duplicate. Makes a copy of the highlighted motor in the custom motor list.

- Delete. Deletes the highlighted motor in the customer motor list.

- Import. Allows you to import a motor file (*.motor) from another location

- Export. Allows you to save the highlighted motor file (*.motor) to another location

- Apply. Accepts the values you have entered for the specific motor files you are entering.

- OK. Returns you to the Motor Selection screen.

When entering any of the motor data, be certain the units are correct. The AKD2G drive uses the motor parameters to set up the various feedback loops and limits associated with the motor selected.

Note that if you select a custom motor from the list and click OK, then that selected custom motor will be displayed in the Select Motor screen.

See also Non-Plug and Play Feedback Devices.

Validating Motor Parameters

When you click OK in the Select Motor screen, WorkBench validates the range with the drive. If any error is found, an error screen is displayed. Click Continue to set the motor parameters in the drive. Click Cancel to close this screen.

If errors occur while setting the motor parameters, an error screen indicates which parameters require additional attention.

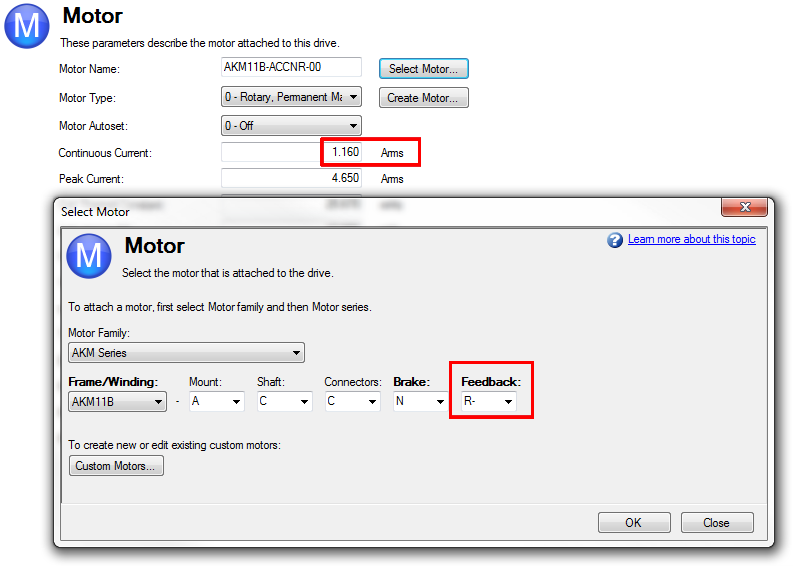

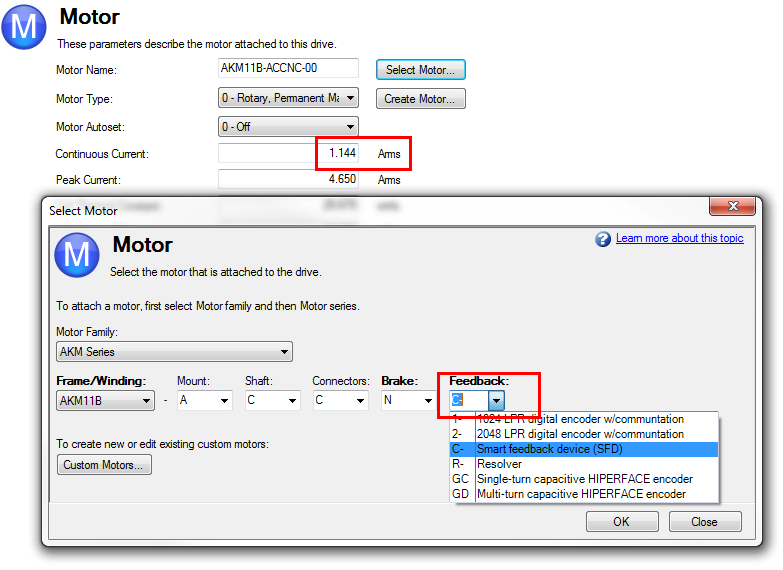

Motor Derating

Motor derating occurs while using a motor in the AKM or VLM series. If a brake is selected or a feedback type other than Resolver is selected, the continuous current will be derated.

Resolver with no brake (no derate):

SFD with no brake (derated):

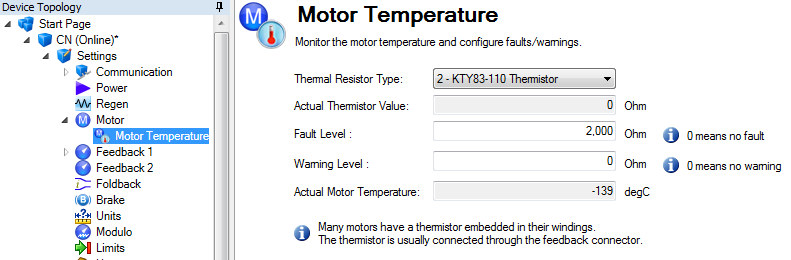

Motor Temperature

Motor Temperature

The motor temperature settings are located in the nested Motor Temperature view.

The thermal resistor type can be selected from the view, or set with AXIS#.MOTOR.RTYPE. The thermal resistor type is set automatically when AXIS#.MOTOR.AUTOSET = 1 and the feedback memory version is 0.3 or greater. The following table provides the thermal resistor types, and the versions of motor memory that support them.

| AXIS#.MOTOR.RTYPE | Thermal Resistor Type | Motor Memory Version |

|---|---|---|

| 0 | PTC | 0.3 and later |

| 1 | NTC | 0.3 and later |

| 2 | KTY83-110 | 0.3 and later |

| 3 | KTY84-130 | 0.3 and later |

| 4 | PTC + KTY83-110 | 0.3 and later |

| 5 | Thermal switch | 0.3 and later |

| 6 | PTC + PT1000 | 0.3 and later |

| 7 | PTC + PTC | 0.3 and later |

| 8 | PT1000 | 0.3 and later |

| 127 | No sensor |

0.4 and later |

| 255 | No sensor | 0.3 only |

If your motor has thermistor with linear characteristics (AXIS#.MOTOR.RTYPE = 2, 3, 4, or 8), the Actual Motor Temperature field will display the measured motor temperature in degrees C (AXIS#.MOTOR.TEMPC). For other values of AXIS#.MOTOR.RTYPE this field will be hidden.

Related Parameters